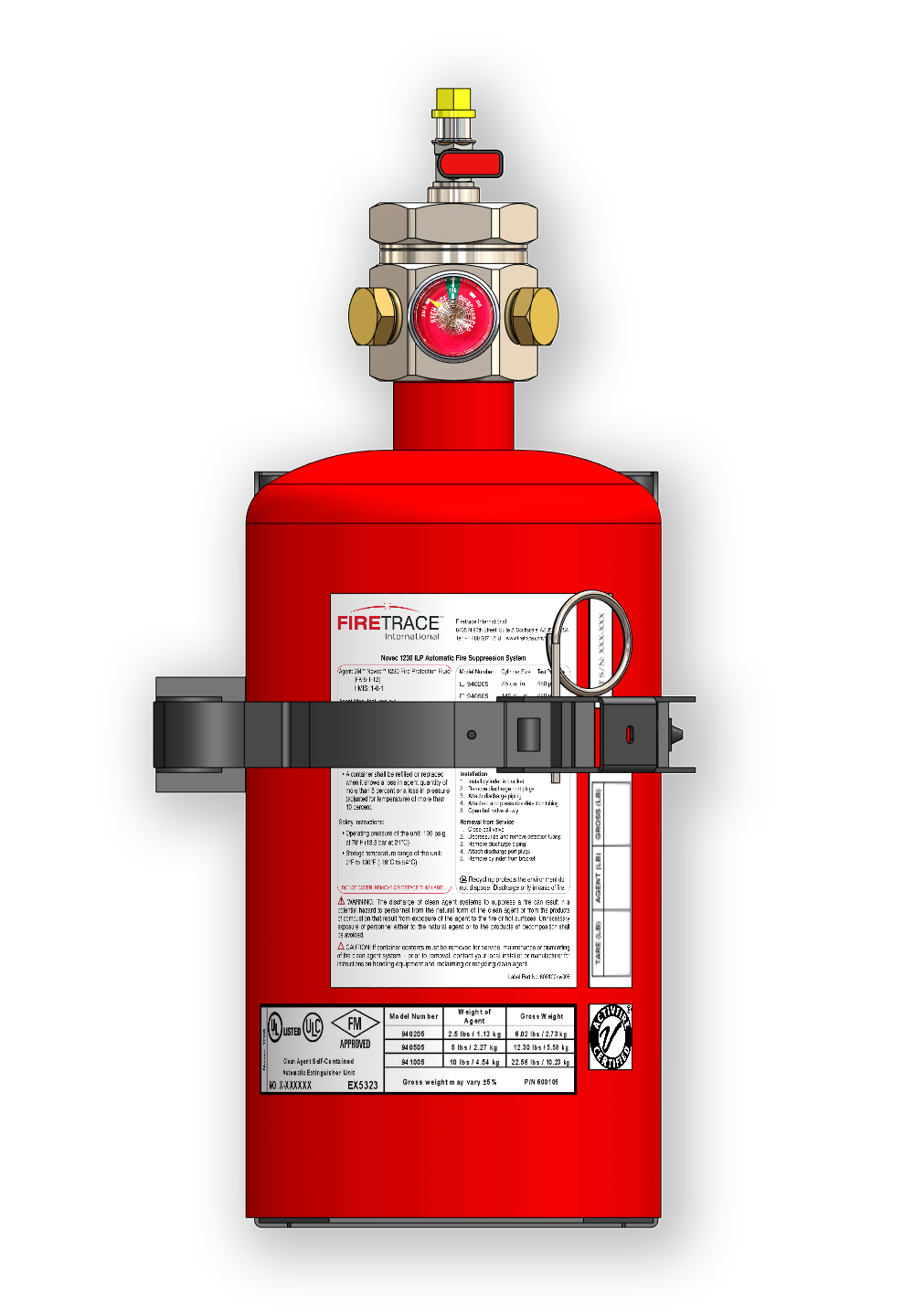

Fire suppression systems are big investments for small shops like ours, but after seeing what the system can do and with running unattended, it's critical for any machine we buy from now on to have it.

Dan Rudolph, Owner

You’d have to be out of your mind to not buy a Firetrace system if you have a machine that has oil coolant. I would never put myself at that risk.

John Koerner, Owner

I can have a machine catch on fire – within 45 minutes, I’ll have that machine back up and running production.

Julie Lowry, Director of Facilities & EHS

Firetrace gives me the confidence to run my machines unattended and gives reassurance that mistakes during setup won’t turn disastrous. All my machines have Firetrace, so will my next one.

Dan Fifer, President

Your product has saved this company hundreds of thousands of dollars.