While electrical cabinets and panels are required for most buildings to function, they do come with hazards. Learn about the causes of and ways to prevent electrical fires.

According to the National Fire Protection Association, there are an estimated 33,470 commercial electrical fires each year in the United States, killing nearly 45 people and costing around $1.36 billion in direct property damage. These statistics highlight the importance of electrical fire safety in the workplace to protect a business’s staff, property, and ability to keep working.

Electrical fires can be especially dangerous and costly when they occur in spaces with large volumes of specialist equipment—like substations, server rooms, data centers, or manufacturing facilities. These high risk, high damage areas often require additional fire protection to help mitigate the risk of fire. They also benefit from fire suppression systems which do not damage the delicate and expensive electrical equipment they contain.

This article will look at electrical fires, their causes and prevention in non-home settings. It will also explore the different fire suppression methods for use around electrical equipment to prevent damage.

.png?width=168&height=252&name=electrical-arc%20(2).png)

A great place to begin is by asking the question: how do electrical fires start? In non-home spaces, electrical fires are caused by the following:

Of the 75% of fires caused by electrical malfunction or failure, nearly half are related to arcing. So— What is an electric arc? Electrical arcing occurs when a current jumps across a gap between conductive materials. This arc can reach temperatures of over 10,000 degrees Fahrenheit and combust flammable gases, dust particles, or other materials it encounters.

An electrical fire is any fire that includes live currents or electric equipment. These types of fires are more common in industrial settings that have higher volumes of high-powered electrical equipment like transformers, electric tools, appliances, and motors.

Normally, electric fires cannot be extinguished with water, because the conductive nature of water could make the electrical fire spread or become more intense. Instead, electric fires should be suppressed with non-conductive agents to minimize damage and risk.

Different countries classify fire types differently. Electrical fires are considered:

.png?width=375&height=250&name=electrical-fire%20(3).png)

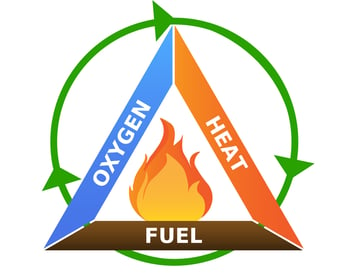

It is helpful to understand the necessary ingredients for a fire to burn. Oxygen, heat, and fuel are commonly known as the fire triangle because fires require these three elements to ignite and burn. Depriving a fire of any or all of these will stop it. The different methods of fire suppression discussed later in this article will rely on depriving a fire of one or several of these necessary components.

The high cost and known causes of electrical fires in commercial and industrial settings highlight the importance of fire safety at the workplace. As discussed above, there are several electrical fire hazards that are most likely to cause a workplace fire. Let’s look at each and find out how to prevent electrical fires.

.png?width=238&height=286&name=electrician-working-on-electrical-panel%20(1).png) Electrical or mechanical malfunction or failure

Electrical or mechanical malfunction or failure

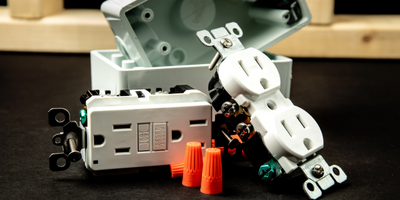

A ground fault circuit interrupter (GFCI) is an electrical device that can either be installed as part of an outlet or electrical system, or onto a power cord for a specific device. The main purpose of these devices is to prevent electrical shock in an individual if their body were to unintentionally complete an electric circuit due to faulty equipment or an accident.

Although they were not designed primarily as a way to prevent electrical fires, GFCIs can reduce electrical fire risks in very specific scenarios due to their ability to cut power in circuits in the case of low current grounding faults. In some wiring cases, the grounding wire is placed between the neutral and hot conductors. If damaged, this cable could then contain two conductors running parallel to each other with only an air gap between them. If an arc occurs across this gap, a GFCI device will shut off power much sooner than a circuit breaker would (at 6 vs. 40 amperes), significantly reducing the chance of fire in this situation.

The first step in fire and electrical safety is recognizing that electricity will always pose a fire risk and needs to be treated with respect and care. This means prioritizing electrical fire safety as a way to protect staff, property, and business interests.

Here are some electrical safety tips to get you started, broken down into four major categories.

87% of workplace electrical fires are caused by electrical or mechanical failure, misplaced combustible material, or overloaded equipment. Finding the places these threats are most likely to occur in your workplace is a big step toward mitigating this risk. Some specific hazards to look for include:

When you have identified areas of particular risk, inspect them regularly as part of workplace safety practices. Fix hazards promptly when they are identified, then develop a schedule for checking on these spaces to notice additional issues as they arise.

For example, an electrical control room has been identified as particularly high risk because staff often leave loose paperwork near banks of electrical outlets. Add the task of looking for this fire risk and removing it as part of the daily rounds for a safety officer.

Working fire alarms should be in place and regularly tested in all workplaces. Areas of high risk should also be equipped with an effective fire suppression system as well.

All staff should receive training on fire safety best practices, as well as how to use any relevant fire suppression system. In our example above where staff were leaving paperwork in the electrical control room, educating staff on why this constitutes a fire hazard can make the workplace a safer environment. It is also important to have an evacuation plan in place and train workers how to follow it.

When looking at how to extinguish an electrical fire, it's important to note what a fire extinguisher is. A fire extinguisher is a portable piece of equipment that sprays water, gas, dry chemical, or foam in order to put out a fire. They are sprayed by a person and generally used on small fires just as they are beginning, when they can be used safely. This contrasts with other fire suppression systems that can cover larger areas and do not require direct human intervention, which we will cover in the next section.

When looking at how to extinguish an electrical fire, it's important to note what a fire extinguisher is. A fire extinguisher is a portable piece of equipment that sprays water, gas, dry chemical, or foam in order to put out a fire. They are sprayed by a person and generally used on small fires just as they are beginning, when they can be used safely. This contrasts with other fire suppression systems that can cover larger areas and do not require direct human intervention, which we will cover in the next section.

Fire extinguishers can be classified in two ways—by the type and size of fire they will best extinguish and by the type of extinguishing media they contain. Extinguishers are usually labeled clearly with both pieces of information. For electrical fires, the extinguisher should contain non-conductive media, such as dry powder, carbon dioxide, or a clean agent. It should also be labeled with the electrical fire class, which varies by country (Class C in USA, Class E in Australia, Unclassified in EU/India).

Let’s take a closer look at the different types of fire protection systems and why each would or wouldn’t be appropriate for electrical fires and fires around electrical equipment.

Safe Extinguishing Mediums for Electrical Fires

Because of its high level of importance, fire safety in the workplace regulations exist around providing appropriate fire suppression methods based on workplace hazards. These will vary by country since different regulatory bodies control requirements.

In the United States, the Occupational Safety and Health Administration (OSHA) has the following requirements for portable fire extinguishers:

Fire extinguishers are vital, life-saving pieces of equipment—if they are available and used correctly at the right time. However, they require a person to see a fire while it is still small enough to be put out safely with a portable extinguisher. The extinguisher also must be near enough and visible enough in an emergency situation for a person to be able to quickly access them. Finally, they require that the person using them does so in a way that effectively contains the fire.

Fire extinguishers are vital, life-saving pieces of equipment—if they are available and used correctly at the right time. However, they require a person to see a fire while it is still small enough to be put out safely with a portable extinguisher. The extinguisher also must be near enough and visible enough in an emergency situation for a person to be able to quickly access them. Finally, they require that the person using them does so in a way that effectively contains the fire.

Because portable fire extinguishers only work to stop a fire if all these conditions are met, there are many situations where an alternative form of fire suppression is advisable. Other suppression systems include: