Customer Background and Incident

Absolute Turning and Machine in Tucson, Arizona manufactures aerospace parts and other components that require high speed, precision manufacturing methods using oil-based coolants to machine metal alloys. After experiencing fire incidents in previous companies, the team decided they needed to get fire suppression systems installed in their Citizen machines when they were purchased back in 2017.

The fire incident occurred on a Citizen L-32 Swiss Turning Machine around 6 a.m. on Saturday, June 1. After turning on the machine, it ran for 30-40 minutes when suddenly a spark was created between the tool and the 304 stainless steel that was being machined, igniting the oil-based coolant. Upon further inspection after the incident, the cause of the spark was the coolant tube being bumped, so it was no longer spraying coolant on the area being machined.

Save and Aftermath

The operator standing nearby immediately hit the E-Stop and turned to grab an extinguisher but realized the automatic fire suppression system installed on the machine had already suppressed the fire before he even turned around. The operator estimates it only took two seconds for the system to discharge, saving the machine from any damage the fire may have caused. Only the tool was damaged, with minor burn marks found on the tip.

Once the fire was suppressed, the machine was inspected, and the cause was identified. Due to an operator error, the coolant tube was not in the proper position to cool down the cutting surface. The team decided it was best not to disable the pressure switch to return to production because they did not have an extra cylinder to exchange to get the system back up and running with fire protection and did not want to take the risk. In total, the system was down four days before a distributor came out to replace and recommission the system.

Their other two machines do not have fire suppression, but they are now working to get it installed after seeing how quickly and effectively the system engaged once the incident occurred.

Effect of Suppression System

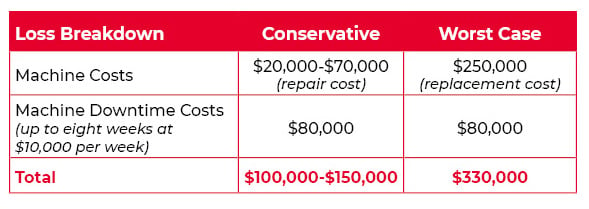

Had the machine been completely lost in the fire without the suppression system, the team estimates it would cost nearly a half of million dollars in lost assets and downtime and machine replacement cost. If the machine were to be salvaged, the downtime and repairs alone could cost anywhere from $100K-$150K depending on the severity of the damage, had it occurred.

Had the fire not been suppressed as quickly as it was, it is very likely the machine would have been lost. This would have cost over a month of downtime to get it replaced, not to mention it could have damaged other parts of the shop, and even put employees at risk. For just a fraction of the machine cost, the investment in a fire suppression system was able to keep their assets, employees, and business safe.

“every employee is so thankful that this system was in place.”

- Swami Subramanian, Owner

Conclusions

This machine shop avoided costly downtime, repairs, and injury with an automatic fire suppression system. This case shows how Firetrace systems can help save customers valuable time, money, and improve safety in their manufacturing businesses.