Customer Background and Incident

Engineered Machining Solutions (Orange, CA) manufactures aerospace parts and other components that require high speed, precision manufacturing methods using oil-based coolants to machine metal alloys. As production demand has increased, they made the decision to purchase a new CNC lathe two months back and had a Firetrace system installed because of the risk involved in cutting metal with oil.

The fire incident occurred on a Tsugami BO385C Swiss Type Lathe on Tuesday, May 28. One of the operators walked out of the bathroom to see what they thought was smoke in the shop, it was actually the clean agent. He walked over to the machine and saw that there had been a fire. Due to a tight schedule from a demanding customer, the machine was being pushed to run 28-second cycles to machine 17-4 stainless steel parts.

Save and Aftermath

One of the other operators standing nearby said the fire suppression system engaged instantaneously to suppress the oil fire before any damage to the machine could occur. The pressure switch installed with the system immediately shut down the machine and coolant flow to prevent reignition of the fire.

Once the fire was suppressed, the machine was inspected, and the cause was identified. With the amount the machine was being pushed, a tool broke, causing a spark and igniting the hot oil in the machine. The only damage was to the tool and some of the material being machined. The machine only experienced minor charring that was easily cleaned off. A local Firetrace distributor was out within 24 hours to get the system replaced, and the machine back up and running.

Their other swiss machine does not have fire protection, but they are now looking to install it after seeing how reliable the Firetrace system was in suppressing the incident.

Effect of Suppression System

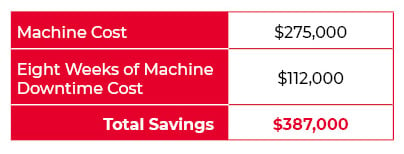

Alexander Nachurski, the operator who caught the save, was thrilled with the fire suppression system. Without it, he believes they would have lost the machine. This would have set them back $275,000 for a new machine replacement, and at least eight weeks of downtime during the replacement process. The machine continuously turns out parts all day, which would have created a loss of $14,000/week if the fire had not been suppressed.

Along with the risk of losing the machine, there was also the risk of the fire spreading to other areas of the shop. Had the fire suppression system not been in place, the safety of the employees and the business would have also been at risk.

Along with the risk of losing the machine, there was also the risk of the fire spreading to other areas of the shop. Had the fire suppression system not been in place, the safety of the employees and the business would have also been at risk.

“Anybody that turns any kind of metal knows the risks of

the hot oil with the process, so for me investing in the system

is really a no brainer.”

– Alexander Nachursk

Conclusions

This machine shop avoided costly downtime, repairs, and injury with an automatic fire suppression system. This case shows how Firetrace systems can help save customers valuable time, money, and improve safety in their manufacturing businesses.