What Is CNC Coolant Made Of?

There are four different kinds of CNC coolant, all of which are made of different materials and are used for different reasons. They are:

- Synthetic fluids: This type of coolant is water-based and contains organic and inorganic alkaline materials and ingredients. It protects the workpiece from corrosion and overheating.

- Semi-synthetic fluids: These mix synthetic fluids and mineral oils. They are good for transferring heat.

- Soluble oils: This type mixes mineral oil, water, and emulsifiers to keep the oil and water mixed. This one is also good at transferring heat and is typically the most affordable type of coolant.

- Straight oils: These are made up almost entirely of either petroleum or mineral oil and may include vegetable oils. They do not work well to cool your CNC machine, but they do help to lubricate it.

Typically, CNC coolants are used to help:

- Cut materials such as fiberglass, metal, and plastic

- Keep the machine cool when working at high speeds

- Lubricate moving parts

- Protect the machine from corrosion

- Lengthen machine life

- Keep the workspace clean of debris

Despite their effectiveness in making CNC machines run smoothly, coolants come with risks.

Is CNC Machine Coolant Flammable?

Because many CNC coolants are oil-based, they are extremely flammable. If the improper amount of coolant is used, heat can build up until a fire starts. Combined with the friction and heat from a machine working at high speeds, the chances of a fire starting increases. Plus, having a workspace covered in debris will also present a fire hazard when using a CNC machine. That’s because that debris can easily catch on fire if a spark hits it.

CNC machines may catch on fire if a tool is installed incorrectly, used incorrectly, or if a tool breaks. Fires start in these situations because the broken or improperly installed tool can hit another part of the machine and set off sparks. Thus, extreme caution should be used when handling a CNC machine. Installing a CNC fire suppression system will help prevent damage should a fire start in your manufacturing areas. Additionally, putting a fire recovery plan in place can prepare you and your team in the event of a worst-case scenario.

What Is a Fire Suppression System?

A

fire suppression system is designed to quickly control and suppress fires after they start. They may also come with a signaling system to alert personnel of a fire so that they can take further action if needed.

An automatic fire suppression system will go off on its own if it recognizes smoke and/or heat. A common type of automatic fire suppression system is a

water sprinkler. A manual system, on the other hand, requires someone to activate it. A common example of this type is a hand-held fire extinguisher.

How Does an Automatic Fire Suppression System Work?

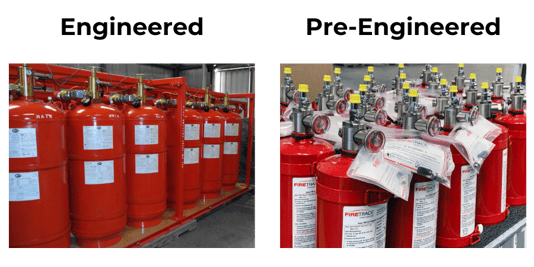

For an automatic fire suppression system to work, it needs to be installed in the areas that are at the highest risk of fire. How much of the room it covers depends on which type you use. Firetrace offers two types of automatic fire suppression systems:

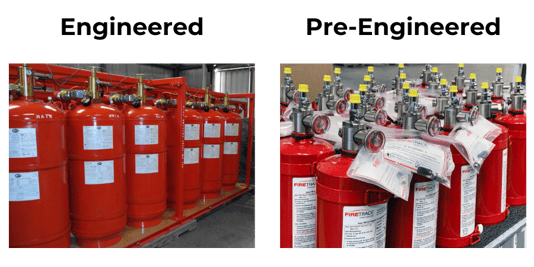

- Engineered Fire Suppression System: This covers a larger space, like server rooms and electrical switch rooms. It will use gaseous clean agents to put out fires.

- Pre-Engineered Fire Suppression System: This protects smaller spaces from fires, such as storage areas, electrical cabinets, and CNC machines. It usually uses clean agents or CO2 to extinguish fires.

To detect the fire, an automatic fire suppression system will use either an active or a non-electrical detection system. The active system must be connected to electricity to monitor for extreme heat or smoke. When a device within the system senses one of these, it sends a signal to release the suppression agent. Non-electric systems, on the other hand, do not use electricity to work. Firetrace pre-engineered systems fall into this category. Our red Firetrace Detection Tubing (FDT) bursts when exposed to heat, releasing the fire suppressant agent and suppressing the fire.

The type of suppression agents within these systems will vary depending on the type of fire expected in the area where it’s located. You may have heard of UVIR detectors - check out our UVIR Detector Case Study to find out how this method worked for a tool manufacturing company in the south.

What Are the 4 Types of Suppression System Extinguishants?

When it comes to CNC fire suppression, there are a few different types of fire suppression agents to choose from. Here are some examples:

- Gaseous Clean Agent: They work by reducing the amount of oxygen the fire gets. The clean agents are typically made of argon, nitrogen, and carbon dioxide. These agents evaporate and do not leave a residue.

- Chemical Agent: This type comes in both wet and dry forms. The wet form is usually made with potassium acetate and potassium citrate. It dispenses as a foam and stops the chemical reaction between the fuel (usually oil or fats) and the oxygen. Dry chemical agents are typically made of potassium bicarbonate, sodium bicarbonate, and monoammonium phosphate. This agent suppresses fires by separating the fuel and oxygen.

- Carbon Dioxide: This suppression system displaces oxygen to extinguish fires. It leaves little to no residue, so cleanup afterwards is not necessary.

- Water: When excessive heat reaches water sprinklers, it will release water to reduce the heat of the fire until it’s extinguished. This system is not ideal for machinery fire suppression because it can damage expensive equipment.

To determine which fire suppression agent works best for you will be based on the type of fire you might expect, what areas you need protected, and other special considerations.

What Is Used in CNC Fire Suppression Systems?

CNC machine fire suppression systems use other agents instead of water. That’s because in the case of machines, water will not work and may even make the fire worse. To better understand why that is, let’s look at some of the classes of fire typically associated with machines..gif?width=143&height=286&name=flame-gif%20(1).gif)

- Class B: These fires most often happen in industrial settings because the common sorts of fuels that start them are gasoline, oil-based coolants, and propane. Putting water on these fires is not effective because water is typically denser and has a lower boiling point than the fuels in these fires burn. That means when water is poured on these types of fires, it creates steam and can spread the fire. Dry chemical agents, clean agents or a CO2 fire suppression system work better to suppress these types of fires.

- Class C: These fires start due to electrical currents. Putting water on these flames can spread the fire since water conducts electricity. Overall, chemical agents or clean agents work best to put these out.

- Class D: This type of fire usually occurs in manufacturing facilities or laboratories as they involve combustible metals like aluminum, lithium, and potassium. Some of these metals will explode if water is poured over them while on fire. Dry chemical agents, on the other hand, work well to absorb heat and cut oxygen off from the fire. Learn more about our Class D offering here.

Understanding what class of fire is most likely to occur at your workplace will allow you to make a better decision concerning what agent to use in your suppression system.

Specialists can also help you discern what may be optimal for your application.

Which Special Hazard Fire Protection System Would Most Likely Be Used for a CNC Machine?

CNC fire suppression systems tend to be pre-engineered systems utilizing pneumatic heat detection tubing kits. The tubing can easily fit within the machine and put out fires ten times quicker than other methods. This means less damage to the machine and less risk for your employees. Plus, the clean agents used within the system will leave no residue behind, so you won’t have to worry about cleaning that up or harming your employees..png?width=220&height=205&name=CNC-operator%20(1).png)

While these systems will stop fires once they start, you should take steps to protect your machine from fire to prevent them from happening, such as:

- Perform regular maintenance on your machine

- Confirm all parts work as they should and are not broken/corroded

- Promptly replace parts as needed

- Clean work areas to reduce debris around machines

- Train employees on proper use of machines to avoid overworking or damaging equipment

What Is a Firetrace System?

At Firetrace, our Pre-Engineered fire suppression systems are made of a fire suppression cylinder connected to pneumatic Firetrace tubing, pressurized with nitrogen that can detect both heat and flames. These agents eliminate heat or oxygen to stop the chemical reaction that causes fire. Although our systems are automatic, we often include a manual release in the event an operator sees a fire starting before the Firetrace system activates automatically.

We offer two main types of systems:

- Direct Release: The clean agent comes out directly through the tubing. The point where the most fire or heat is detected is where the tube bursts. The agent discharges into the space where the fire is, suppressing the fire. This type of system works best for electrical cabinets.

- Indirect Release: The agent discharges through the hoses and out of the nozzles. When the detection tubing in the space detects the fire and bursts, it triggers an indirect valve to release the agent through the hoses and nozzles. This system type works better in larger areas and in CNC machines. It's available in low-pressure and high-pressure forms.

Safety is a top priority for machine shop owners and managers - that's why over 15,000 machine shops count on Firetrace systems to suppress fires in a matter of seconds. If you have questions or would like to request more information, don't hesitate to reach out to us.

To learn more about machining fire protection, check out our additional resources:

CNC

EDM

Dust Collector

.gif?width=143&height=286&name=flame-gif%20(1).gif)

.png?width=220&height=205&name=CNC-operator%20(1).png)