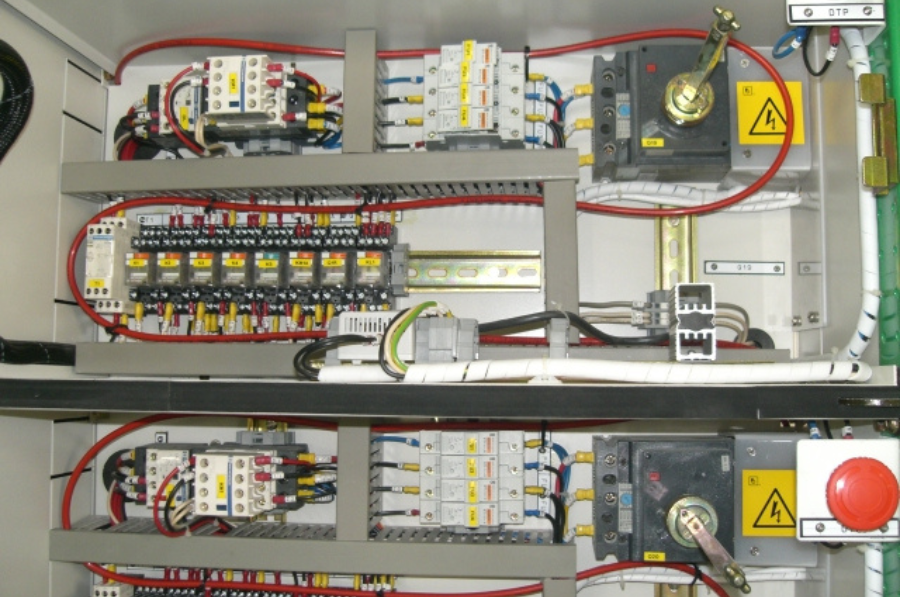

Electrical arcing and other malfunctions can easily start a fire inside of your electrical equipment. Fires can start anywhere there is an electrical connection, and it's important to detect them right at their source. Firetrace systems detect fires using flexible tubing that can be installed anywhere a fire can start. If electrical equipment catches fire, the tubing bursts open, dousing the fire with clean agent gas. Unlike water or carbon dioxide, clean agents will not damage sensitive electronics, making them ideal for electrical equipment.

When the detection tubing reaches a critical temperature, it bursts, releasing the pressure of the system. As a direct release system, the fire-suppressing agent discharges through the burst hole in the detection tubing. You can see the tubing recoil with the force of the discharge upon rupture, and then quickly suppressing the fire.

Our systems use a clean agent to suppress the fire, which cause no damage to the electrical equipment.

Traditional fire detectors provide only a single point of detection. If a fire starts far away from the detector, then it may grow very large before triggering the detector. Firetrace systems detect fires with flexible tubing that can be placed throughout the equipment, providing instant detection at the source of a fire.

Firetrace systems use clean agent gas to suppress fires inside electrical equipment. Unlike water, carbon dioxide, and other chemicals, clean agents are safe for electronics. Clean agents also leave no residue, so they do not require clean up. Finally, clean agents are safe for people, which means you can use them to protect equipment and rooms where people are working.

Most fire suppression systems contain metal components. The problem with metal components is that they can cause electrical arcing. Since electrical arcing is the #1 cause of electrical fires, suppression systems with metal nozzles can actually increase fire risk. Firetrace DLP systems can deliver suppression gas straight through the detection tubing, eliminating the need for metal nozzles.

Can you trust your fire suppression system to work when you need it? Fortunately, several testing organizations independently evaluate fire suppression systems from different manufacturers. The evaluations include live fire tests and semi-annual audits of manufacturing processes. Firetrace clean agent DLP systems hold a third party certification from the Loss Prevention Certification Board (LPCB).