The key to having an optimal finished part starts with choosing the right material. By narrowing down the types of machining materials that are best suited for the part will lead to the selection of the most appropriate and cost-effective material. Here are a few things to consider when selecting materials.

How is the part being used?

Is the part a medical device, automotive, aerospace, mechanical, value, fitting, fasteners, etc.

Stress load

Certain materials will strain or even break under high-stress loads. Make sure to account for the stress load when determining which material to use for the part. Parts exposed to high-stress require machining from material with elements that resist stress loads and prevent deformation.

Dimensional Tolerance

Never underestimate the importance of dimensional tolerance. It doesn’t just have a role in the selection of material; it will also influence the parts and assemblies, cutting methods, and usage of tools and machines. Dimensional tolerance impacts how well your entire process works and the bottom line.

Operating Temperatures

When selecting a material, the melting point of that material needs to be lower than the operating temperature of the machining process. In addition, any fluctuations in operating temperature must be taken into consideration. The material needs to withstand the temperatures without warping, distorting, or breakdown over time.

Material Weight

The weight of the machined material is dependent on how the part will be used. While heavier materials absorb a great deal of stress, they are not suitable for weight-sensitive projects. Lightweight materials are durable and can absorb a considerable amount of stress, but they come at a higher price tag.

Overall Cost and Functionality

When selecting a machining material, many factors will contribute to the decision. To find the most compatible material, prioritize the characteristics most important for your finished part. Selecting a material that meets the strength profile, temperature restrictions, and fitment requirements. Eliminate materials that don’t meet these requirements, compare material costs, and make the selection.

Common Materials Used in CNC Machining

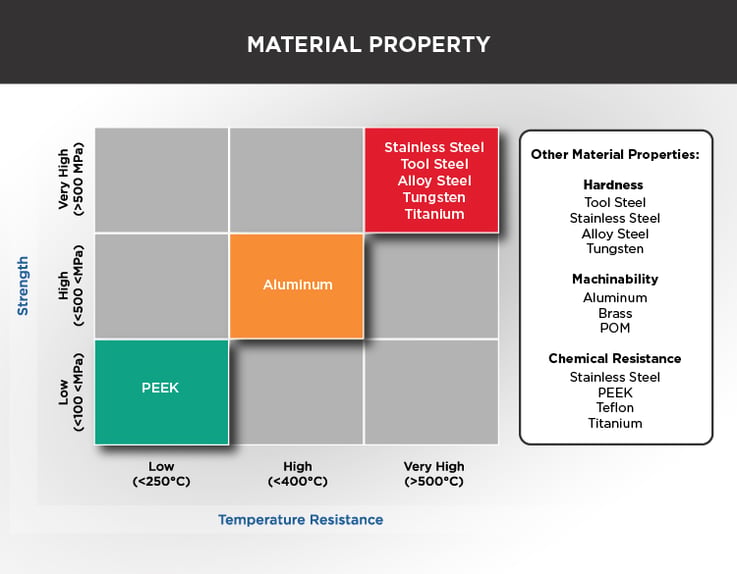

CNC machining can produce parts from nearly any metal or plastic. Applications and parts that require high strength, hardness, and thermal resistance generally use metals. Lighter weight plastics are commonly used for parts needing chemical resistance and electrical insulation. Below is a quick reference chart for properties of common materials used in CNC machining.

As CNC machining has expanded over the years, so have CNC machine parts. Materials can be used for a variety of parts that have significantly different uses. This creates a challenge in selecting the right material for the right part. Just remember to define the material requirements, identify appropriate materials, and then select the most suitable material for your machining operations.