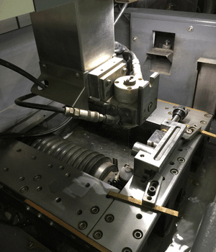

Electrical Discharge Machining (EDM) uses a controlled thermal erosion process to remove metal from a workpiece to create a desired design. These machines are designed to be as safe as possible from the risk of fire, but unfortunately, accidents happen, and you want to ensure operators and equipment are unharmed. The key to protecting against fire is fast and reliable detection and suppression that is not prone to false discharges.

What are the Methods of Fire Suppression for EDM?

The two most popular methods of suppressing fires for EDM are automatic fire suppression systems and traditional extinguishers. The automatic systems are, in most cases, more efficient and safer, but let's have a closer look.

With traditional methods, like a handheld extinguisher, the operator must locate and grab the extinguisher, plug the pin, and aim the extinguisher at the flame. This can be an extremely dangerous task as the fire is being fueled with oxygen. This can cause the fire to grow exponentially. To mitigate this risk, the operator has to manually shut down the machine beforehand. While this process is a good safety measure, it wastes valuable time that could be spent putting out the fire. Only a small amount of time is needed for a fire to become uncontrollable. Even an additional 10 seconds is too much to pass for an EDM fire.

How does an automatic fire suppression system work? With an automatic fire suppression system, an operator does not need to get near the machine during a fire. These systems react to a rapid rise in heat or other traces of fire without any human intervention. These systems contain the same general components:

- Detection elements, such as pneumatic tubing or a smoke detector

- Suppression agent cylinder

- Pressure switch (optional)

- Manual release (optional)

For EDM machines, the agent of choice of CO2, which is nonconductive and noncorrosive. This means that while they put out the fire, the machine will not be harmed.

Benefits of Automatic Fire Suppression

EDM, Dust Collector, and CNC machine fire protection such as fire suppression systems provides value for both the operators and machines, such as:

- Earlier Detection: Human reaction time will never be able to beat automatic software inside these systems. These systems are able to detect a fire within seconds, extinguishing it before it grows too large to control, which minimizes damage to the machine and operators.

- Less Risk: By not requiring the operator to get involved in the suppression process, you significantly reduce the risk of injury to any and all employees. There is also less risk involved with the machines as well. During the height of an intense moment like a fire, human error is commonplace. A well-intentioned employee could accidentally make matters worse.

- Customizable: You have the ability to tailor automatic systems to your needs. CO2 and gaseous clean agents are perfect for areas with a high density of electrical components. Liquid chemical agents could then be utilized in most other places.

What is the Most Effective Fire Suppression System?

There are two main automatic fire suppression system types: non-electrical and electrical. One is not better than the other. The decision will come down to which type best fits your building and operation area. The main difference between the two is that the electrical systems have an electronic actuator (the non-electrical systems work just as well at suppression, just operating in a different manner). This means a signal is sent to the electronic device to activate the system as soon as it senses something is wrong.

When Should you Get an EDM Fire Suppression System?

It’s best to get an EDM fire suppression system when you install your first machine. The more pertinent question comes down to where the systems should be placed. Your building code and regulations should outline where the equipment needs to be located.

You will also need to consult the various governing bodies that dictate safety requirements within an organization. These will vary depending on your location, but some well-known ones include:.png?width=99&height=116&name=iso-graphic%20(1).png)

- OSHA: Occupational Safety and Health Administration

- NFPA: National Fire Protection Association

- ISO: International Organization for Standardization

- CCCF: The China Certification Center for Fire Products

With fire incidents costing millions of dollars to fix in some cases, having the right fire protection in place is a necessity. There are other steps you can take to ease the impact of fire, such as building a recovery plan and utilizing a UVIR detector.