When it comes to electrical cabinets and panels, fires are more a question of “when” rather than “if.” These fires cost businesses tens of millions of dollars a year in damages, yet fire protection for electrical cabinets is not always required by regulations. In fact, electrical cabinet fire protection is often skimped on or skipped altogether, in part due to the cost of fire suppression systems.

However, for safety-conscious business leaders, fire protection doesn’t have to come with a big price tag. There are different levels of fire suppression systems, including affordable options, that can work to protect your equipment, and more importantly, your employees.

What Are the Various Types of Fire Protection Systems?

The three types of fire protection systems for electrical cabinets and panels are:

● Stand alone systems

● Pre-engineered Systems

● Engineered Systems

Each of these systems have different levels of protection and different pros and cons. When choosing a solution, it’s important to ask yourself "how do electrical fires start?" Knowing the causes of fire and the environment of your electrical cabinets can help you consider the proper fire protection systems.

What Is a Stand Alone Fire Suppression System?

Stand alone fire suppression system is perhaps a bit of a misnomer, since this term refers to individual devices that contain fire suppression mechanisms that are not linked to a bigger system. For example, FlexRope by Firetrace is an innovative and unique product that is the first stand alone fire suppression solution for electrical cabinets. It is a low-cost, easy-to-install, no-maintenance fire protection solution that is designed to protect enclosures as large as 35 cubic feet. This stand alone device is a simple solution to prevent electrical fires in a cabinet or panel from spreading to the entire building.

One way that stand alone fire suppression devices work is by releasing the fire suppressant when the product is activated by heat. In the case of FlexRope, its exterior is a fiberglass braid that protects fire suppressant granules in the center. When the heat/flame temperature in contact with the FlexRope reaches 660 degrees Fahrenheit, the FlexRope activates and the granules are converted into an aerosol like cloud, which suppresses the fire.

What Is a Pre-Engineered Fire Protection System?

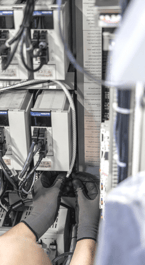

Pre-engineered fire systems are the next level of protection available. They are ideal for small enclosures, like an electrical cabinet or precision machines. When looking at the different types of clean agent fire suppression systems, these solutions are often chosen. These systems utilize fire detection tubing that burst from the heat or flames. In the case of a pre-engineered direct system, the clean agent is delivered directly through burst hole. The indirect pre-engineered systems, delivers the suppression agent through strategically placed nozzles. When using clean agent, the fire is suppressed without damaging the electrical components or machinery they protect..png?width=178&name=firetrace-tubing-wired-through-electrical-panel%20(1).png) Pre-engineered systems are offered with an array of suppression agents that can fight specific classes of fires. However, pre-engineered systems using clean agents will minimize downtime, since the clean agents don’t leave any residue or cause damage to electrical components when the fire suppression system is activated.

Pre-engineered systems are offered with an array of suppression agents that can fight specific classes of fires. However, pre-engineered systems using clean agents will minimize downtime, since the clean agents don’t leave any residue or cause damage to electrical components when the fire suppression system is activated.

What Is an Engineered Fire Suppression System?

An engineered fire suppression system offers the highest level of protection. They are designed to blanket an entire room in a clean agent whenever a fire is detected. For rooms that have multiple electrical panels or other equipment like data centers that needs to be protected from fire and water, engineered systems are often the best choice.

Instead of using water to suppress a fire, engineered systems use clean, non-conductive agents like FM-200™ or FK-5-1-12. This is important in cases of electrical fire, since water can cause damage to equipment or conduct electricity.

Choosing the Right Protection Level for Your Electrical Cabinets

When looking at the three types of protection, it’s important to choose the solution that is right for your space. Solutions like FlexRope are an affordable option for spaces where there are important electrical cabinets that may not be required to have fire suppression but where safety-conscious business leaders are looking to add a layer of protection for their building and employees. Pre-engineered systems work well for mid-sized spaces with multiple electrical panels, and engineered systems are the most comprehensive option that works well for large environments. Electrical fires can, and do, happen— but they don’t have to be devastating. Feel free to call us or request a free quote today.