Oil-Based Coolants: the Good, the Bad, and the Usability

When it comes to CNC machining, there are a lot of options for coolant selection. In machine shops today, around 80-90 percent of applications use a water-miscible fluid. These include soluble oils, synthetics, and semi synthetics. However, in precision machining applications, oil-based coolants are the best option.

What are oil-based coolants?

Oil-based coolants, also known as cutting oil, are petroleum, vegetable, or mineral-based fluids that contain no water. Light ferrous and non-ferrous machining applications use these fluids. In more heavy-duty applications these coolants may contain wetting agents, up to 20 percent fatty oils, and extreme pressure (EP) additives such as chlorine, sulfur, or phosphorous compounds. These additives help improve lubrication and coat the tool, as well as guarding against microscopic welding, which can lead to tool breakage and rough finishes.

What are the advantages of oil-based coolants?

One of the main advantages of using oil as a coolant in the machining process is the “cushioning” effect it has between the machine tool and the cutting material. It helps create high-quality surface finishes and prolongs tool life. Oil-based coolants tend to be the coolant of choice for crush grinding, severe broaching and tapping, deep-hole drilling, and for machining difficult to cut metals such as certain stainless steels, superalloys, and exotic metals like titanium. Along with the lubrication advantages, these coolants are easy to maintain and less likely to cause problems if misused, provide rust protection, and increase sump life., They also resist rancidity due to the lack of water for bacteria to grow.

What are the disadvantages of oil-based coolants?

While they provide a lot of good qualities, oil-based coolants do have some drawbacks. Their heat dissipation ability is lacking, and they can create a mist or smoke that can be harmful to shop operators. This increases the risk of fire, making it important to have proper fire suppression and ventilation systems in place. Oil-based coolants tend to leave an oily film on workpieces and tools, making cleanup more difficult and often requires the use of cleaning solvents.

Is oil the coolant for you?

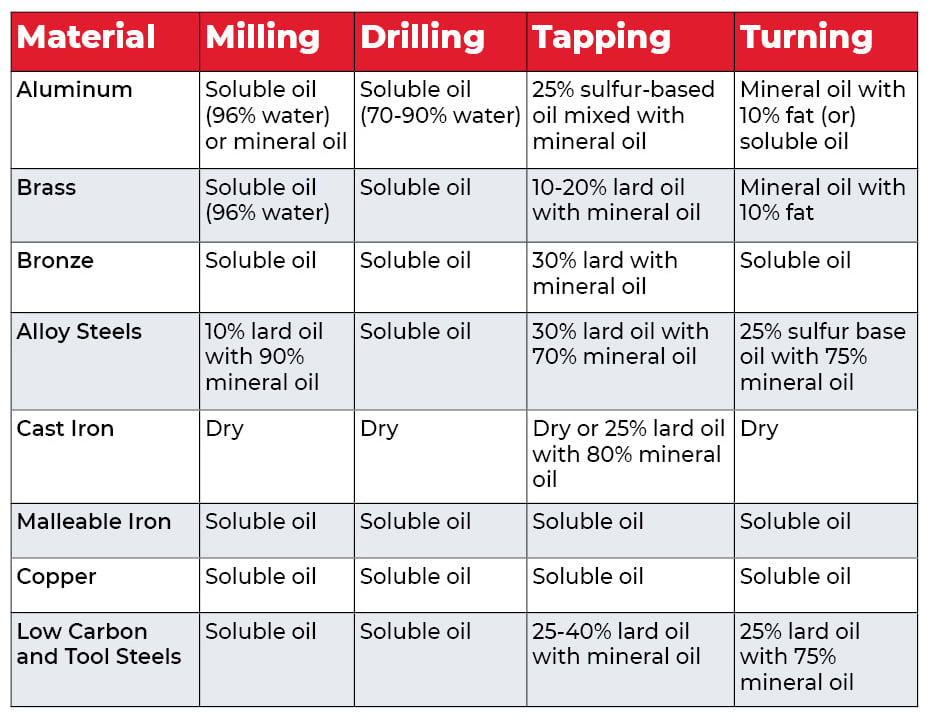

When selecting a coolant to use for machining operations, there are countless options on the market with advantages and disadvantages for each. The table below outlines coolant recommendations based on the machining processes and materials being machined.

In most precision machining and swiss screw applications, oil-based coolants are still the coolant of choice. It is important to ensure the proper safety and protection elements are in place to help mitigate the risk and reap the benefits that they provide.