Understanding the Different Types of Clean Agent Fire Suppression Systems

A clean agent fire suppression system is designed to minimize damage by acting quickly, suppressing a fire at the inception stage before it can grow. These systems are unique in that they are safe to use in occupied spaces, require no cleanup after discharge, don’t damage sensitive documents or equipment, and are environmentally friendly.

A major differentiator between different clean agent fire suppression systems is the type of clean agent being used. The most common types will make use of either chemical agents FM-200™ OR 3M™ Novec™ 1230 Fire Protection Fluid, the brand name of FK-5-1-12, or inert gases like nitrogen, argon, and carbon dioxide.

Generally, these systems that utilize clean agents are suited to situations where traditional water or foam systems would damage equipment or assets, like server rooms, electrical cabinets, data storage, and telecommunications systems, precision machines, repositories holding records or files, artwork, and so on.

Relatively recently, the patent for 3M ™ Novec™ 1230 expired, so it’s worth revisiting what Novec™ 1230 is and how it compares to other alternatives that are in the market. We’ll break it down, starting with a brief history of 3M’s patent.

Novec™ 1230’s History

Back in the early 2000s, 3M™ patented, began manufacturing, and went to market with Novec™ 1230, the brand name of ASHRAE chemical name FK-5-1-12. Novec™ 1230 was a game changer for the fire suppression as this chemical touted a global warming potential of <1. In comparison, the other leading chemical clean agent FM-200™ has a GWP of 3350, according to the National Fire Protection Association. On July 31, 2020, 3M’s patent over FK-5-1-12 expired opening the way for alternate manufacturers to begin producing this highly sought after fire suppression agent.

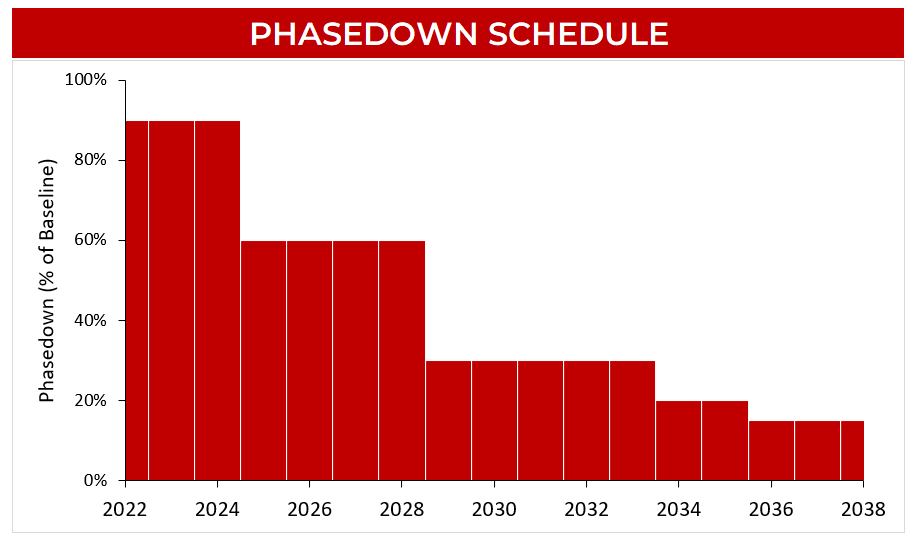

Later that year, on December 27, 2020, the American Innovation and Manufacturing (AIM) Act of 2020 was enacted, which phases down the production and consumption in the US of listed HFCs by 2036, which includes HFC-227ea, the clean agent better known as FM-200™.

The January 2021 implementation of the AIM Act led to an immediate 10% decrease in agent availability and a nearly 300% increase in the cost of FM-200. This caused the need for industry participants to identify alternate means for asset fire protection. These developments created additional demand for 3M™ Novec™ 1230 Fire Protection Fluid (FK-5-1-12)

The most recent development around Novec™ 1230 came on December 20th, 2022. 3M announced plans to exit PFAS manufacturing by the end of 2025, which includes Novec™ 1230 Fire Protection Fluid. Though 3M has committed to fulfilling contractual obligations, the announcement caused many industry participants to reconsider their agent choice.

What does all of this mean for the fire suppression industry?

The need for clean agent fire suppression systems that require no cleanup remains unchanged. So what options are still available?

There are still technically three options available on the market with two being more realistic options for most scenarios.

- FK-5-1-12

- Inert Gas Systems

- FM-200™

As discussed previously, the AIM act is making FM-200 an expensive option due to the increasingly limited production of hydrofluorocarbons (HFCs) and is not likely the best option in most scenarios.

What is FK-5-1-12?

FK-5-1-12 is the ASHRAE chemical name for 3M™ Novec™ 1230 Fire Protection Fluid. This means that FK-5-1-12 manufactured by other companies behaves the same way as it relates to the interaction with fire.

Who are the manufacturers of FK-5-1-12?

There are a wide variety of manufacturers of FK-5-1-12 with more companies entering the space often as this market continues to evolve. Currently, there are five original manufacturers of FK-5-1-12 that are approved by both UL and FM. All of these manufacturers are located in either China or Singapore. There are more companies that offer FK-5-1-12 but they have no listings or are only approved by either UL or FM.

What is FK-5-1-12’s Class A / Class B / Class C MDC? How is this determined?

Each manufacturer that is approved by either FM or UL undergoes a series of tests, much like they testing for fire suppression systems. The approval by UL and/or FM ensures a 3rd party has verified the efficacy of the chemical agent. This testing sets minimum extinguishing concentrations (MECs) for Class A and B fires. These MEC’s are used to calculate minimum design concentrations (MDCs) based on specific calculations as required by FM and UL. These MDCs ultimately determine how much agent is needed to protect specific volumes.

As this testing is done by each manufacturer, there can be variations in performance depending on the manufacturer. For the five UL and FM approved manufacturers of FK-5-1-12, this is how their performance compares:

|

Company Name |

MDC Class A |

MDC Class B |

MDC Class C |

|

3M COMPANY |

4.5 |

5.85 |

4.51 |

|

Zhejiang Noah Fluorochemical Co Ltd |

4.5 |

5.85 |

4.52 |

|

Sinochem Lantian Co., Ltd. |

4.5 |

5.85 |

4.52 |

|

SHANGHAI WAYSMOS FINE CHEMICAL CO LTD |

4.53 |

5.89 |

4.74 |

|

CHEMORI LLC |

4.5 |

5.85 |

5.06 |

As you can see, for Class A and Class B hazards there is very little or no variation between suppliers. For Class C, with some suppliers, there is up to a 20% drop off in performance between the best and worst performing.

What is the Right Fire Suppression System for You?

Whether considering what type of clean agent or inert gas fire suppression system makes sense for your business, clean agent systems pose no significant risk to sensitive equipment, people, or the environment. Clean agents require no cleanup after discharge which prevents costly disruption and downtime, saving you both time and money.

Currently, the two best clean agent options on the market are FK-5-1-12 or inert gas systems. Which one is best for you will ultimately depend on a variety of factors for your specific situation that a qualified fire suppression expert can help you with.